Syscrush wrote:

Having just returned from a resort in DR, that machine looks very familiar.

Yes, I bought a different model than I was originally looking at, this one goes down to -10C (14F) which makes it WAY better for alcohol drinks. In a standard machine you can't have more than about 1 alcohol to 4 parts drink mix but with this one 1:2 works pretty well

Syscrush wrote:

Do I remember right that in addition to the MultiMAP to get a single strong vacuum signal, you're also using something to put the 12 individual MAP sensors onto the CAN bus for logging & diagnostics? I think I wanna do something similar and would appreciate any pointers on how to get that set up...

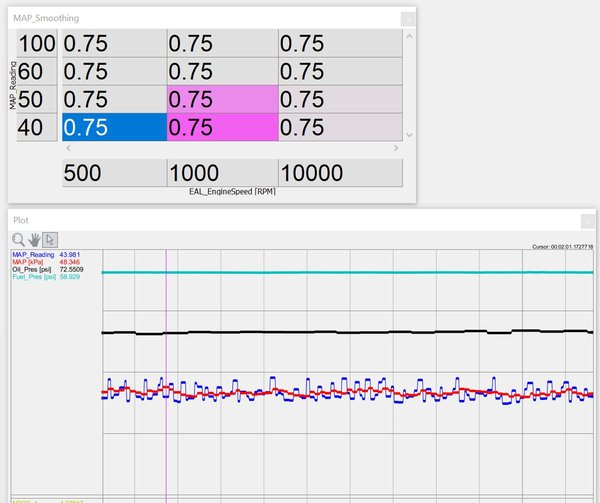

Basically yes but I also use the 12 cylinder signals for cylinder mixture control. The multiMAP has 12 MAP sensor and a simple diode circuit that sends the lowest of the 12 (the cylinder that is actually pulling vacuum) out as the official MAP reading so any ECU can read it. That was the original plan and it works pretty well. I can find so data logs for you but there is a little bit of waviness in the raw signal. Here is the last run, raw reading from the multiMAP is Blue and its bouncing about 10kPa, RED is what I use as the MAP signal and its only bouncing about 3kPa because I do a little digital smoothing on it....its like a running average and the table above tells the ECU how much work to do, that table part is probably over kill and right now you can see everything is set to 0.75 that means I take 75% of the old value and add on 25% of the new value which gets rid of about 75% of the bouncing but causes a little bit of lag so if you look close you can also see the peaks on the red line shifted to the right (lagging) the peaks on the blue line. I think every ECU has something like this built in, so let you adjust it, some its hidden but it almost always there.

Attachment:

Map ripple.JPG [ 122.88 KiB | Viewed 7802 times ]

Map ripple.JPG [ 122.88 KiB | Viewed 7802 times ]

On a 4 cyl vs a 12cyl there will be more bouncing in the signal so you would probably want more smoothing to keep the mixture consistent, but then you'd live with a little more signal lag which can impact throttle blip acceleration but probably not actual driving acceleration because ECUs read the sensors fast, like around 1k-2khz usually so 4 or 10 or 100 readings happens pretty fast and on a 4 cyl you'd be trying to average out about 180 degrees of crank movement, vs me averaging 60 degrees.

Maybe sounds complicated but truly if you just connect the multiMAP to the ECUMAP input it should work just fine

So that is the main MAP signal and the reason I explained that is because trying to read the cylinder MAP is much harder because You're not just trying to smooth out 60-180 degrees of signal, you are trying to

throw out everything except 60-180 degrees of signal and that means more math and most ECUs will not let you do this, all will let you log the signal but not use it for control like I'm doing. I don't recall what ECU you are planning to use, some will let you do math in the log display, others you need to export to excel to do the math.

What I do to get cylinder MAP is:

1) read all 12 cylinders and smooth the heck out of the raw signal...I use 0.99 factor which means I take 99% of the old reading and ad 1% of the new. This is a ton of lag but it doesn't end up mattering because i correct for that.. This number is be about 1/4 true MAP because 3 cylinders are in some part of intake and 9 are not. Same on a 4 cyl, 1 in vacuum, 3 not.

2) Take the average of the 12. This is basically what the output of a small plenum setup to read MAP would be....its a signal that represents MAP but is ever weak because most cylinders aren't doing anything helpful to the MAP signal.

3) Add the magic....the signal from the multiMAP which is the true engine MAP that each cylinder is contributing to. I say:

Cylinder MAP= Cyl reading/(MAP/Cyl average)

This both amplifies the weak signals so that match the actual signal and removes the lag I created trying to smooth out the signal enough to read it and the average of all 12 cylinder reading is equal to the MAP signal, guaranteed.

So now that I have cylinder MAP readings I trust I use them to display each cylinder vacuum to help me sync the TBs and I use them trim the fuel to each cylinder to match its vacuum so in theory each cylinder has the same mixture no matter how buggered the TB sync is which is a really problem for ITBs that normally don't correct cylinder mixtures vs individual carbs that do correct, not perfectly but way better than nothing you get from most EFI ITB setups

I read the 12 cylinder MAP signals from the 12 MAP sensors on the multiMAP. I had to use a CAN expander because I didn't have an extra 12 analog inputs on the ECU so CAN was the only way I could read them.

That's what I do and it seems to work pretty well. We can move the discussion you your particular setup to your thread or email as it will be different from mine unless you use an ECU like mine.