MerlinTech wrote:

What about embossing the plate around the coolant passages to help it seal? Like a MLG.

I don't see sealant lasting over the long haul. I see it as a helper but it this case, it is the main ingredient.

Embossing works with MLS because they are like leaf springs, the thin layer can flex quite a bit without yielding

In general I trust a lot of sealing trust to sealant, engine to trans, the intakes to the heads and such so sealant deosn't scare me. But while I was stacking 20k+lbs of patio stones I don't need but my wife got for a great price the last couple days it occurred to me that in my new design there is nothing supporting the o-rings between the cylinders so when I get it to pass the bench test and installed in the car, it will blow out the orings when it starts. Then I though I could make the copper rings taller and yield them on assembly to mostly seal, but then the hoop stress will be 6-8 times their yield stress so getting this setup to pass a bench leak test is a pointless exercise I think. I'm not yet sure what it the3 next attempt will be.

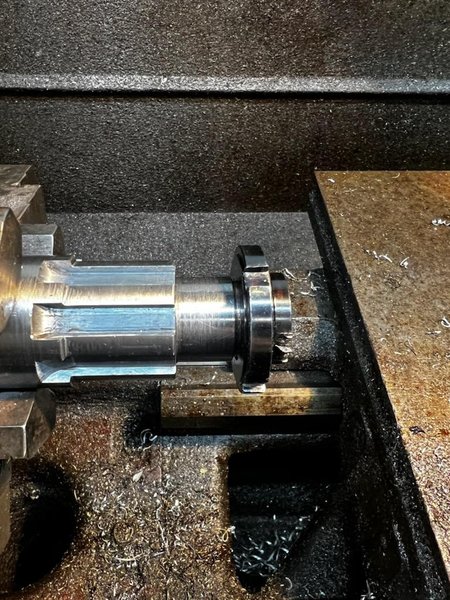

In happier news, the trans shaft now has threads so the ring nut fits, thank you Sean.

Attachment:

af276dff-0a7c-411e-af42-5a571e8e8c98.jpg [ 192.45 KiB | Viewed 636 times ]

af276dff-0a7c-411e-af42-5a571e8e8c98.jpg [ 192.45 KiB | Viewed 636 times ]