Change of subject. I've been back to thinking about sealing the heads. The basic plan is a copper flame ring, viton oring, aluminum shim plate like this

Attachment:

new gasket.JPG [ 106.23 KiB | Viewed 10322 times ]

new gasket.JPG [ 106.23 KiB | Viewed 10322 times ]

The oring is a .070" cross section. Looing at available material thickness, I can get the copper in .050 and aluminum in 0.047 which will guarantee the copper is clamped giving 28-33% compression of the oring, so at to exceeding the high end of spec. That should yield a sealing force of 1500-2000psi which should be above what I need. Great.

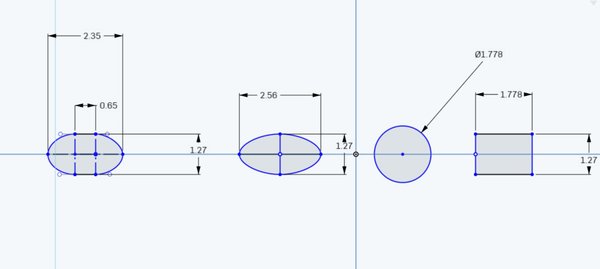

Now the concern is I'm using to the oring to align the flame ring but the oring needs room to grow radially when its being compressed axially. Below are a few cross-sections. On the right is a rectangle .070 wide by .050 tall (1.778x1.27mm) and it has an area less than the oring, so that is a no-go. Moving left is the round oring and a couple deformed shapes with the same area (rubber doesn't compress, it deforms so the cross section remains about constant). I don't have FEA software available but I'm pretty sure the far left is going to be close so I need to leave about .0925 (2.35mm), or a clearance of .0225 (.57mm)...which means the oring is really aligning the flame ring until its compressed. I'm thinking I'm going to make the flame ring ID 86.5mm to go with the 86mm bore and just kind of hope that if I stick the flame ring in place with aviation sealant it stays there and the oring can compress out (it will stretch about 1mm to fit over the flame ring). The other option is I my the ID fo the flame ring large enough to to know it can never touch the piston at full 0-compression assembly but that both makes it thinner and lowers compression so yuck.

Attachment:

volume comparison.JPG [ 57.45 KiB | Viewed 10322 times ]

volume comparison.JPG [ 57.45 KiB | Viewed 10322 times ]

Attachment:

gasket gap.JPG [ 95.88 KiB | Viewed 10322 times ]

gasket gap.JPG [ 95.88 KiB | Viewed 10322 times ]