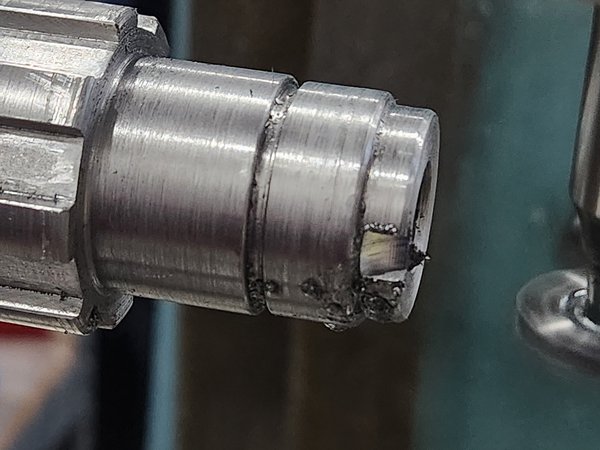

I remembered the shaft needs a couple grooves to peen the nut flange into to lock it so added those

Attachment:

20240107_132223.jpg [ 1.53 MiB | Viewed 17320 times ]

20240107_132223.jpg [ 1.53 MiB | Viewed 17320 times ]

I decided I'd gotten a little greeted on the OD trying to get the most spline contact I could, the OD is supposed to be clearance to the spline but was rubbing so I polished off about .001 and the gear installed as a little press

Attachment:

20240107_135323.jpg [ 2.31 MiB | Viewed 17320 times ]

20240107_135323.jpg [ 2.31 MiB | Viewed 17320 times ]

Attachment:

20240107_133322.jpg [ 3.45 MiB | Viewed 17320 times ]

20240107_133322.jpg [ 3.45 MiB | Viewed 17320 times ]

Then ream the other end. Reamers come with a chamfer cut that I just hate so I always stone a slight radius, it makes them cut a more accurate size and leaves a better finish.

Attachment:

20240107_154626.jpg [ 1.27 MiB | Viewed 17320 times ]

20240107_154626.jpg [ 1.27 MiB | Viewed 17320 times ]

Attachment:

20240107_155054.jpg [ 1.47 MiB | Viewed 17320 times ]

20240107_155054.jpg [ 1.47 MiB | Viewed 17320 times ]

Attachment:

20240107_155653.jpg [ 3.45 MiB | Viewed 17320 times ]

20240107_155653.jpg [ 3.45 MiB | Viewed 17320 times ]

Now I need to make the broach support and a few keys so I can cut, index, repeat.

Attachment:

broach support.JPG [ 41.52 KiB | Viewed 17320 times ]

broach support.JPG [ 41.52 KiB | Viewed 17320 times ]